As we all know, solar panels are designed to last for at least two decades in the outdoors. The operating efficiency of your solar panels, on the other hand, may decrease for a variety of reasons. Here we brought you an in-depth article regarding the 9 most common solar panel defects that surely cause the low performance of your PV system. So you can easily identify these solar panel problems and fix them without hassle.

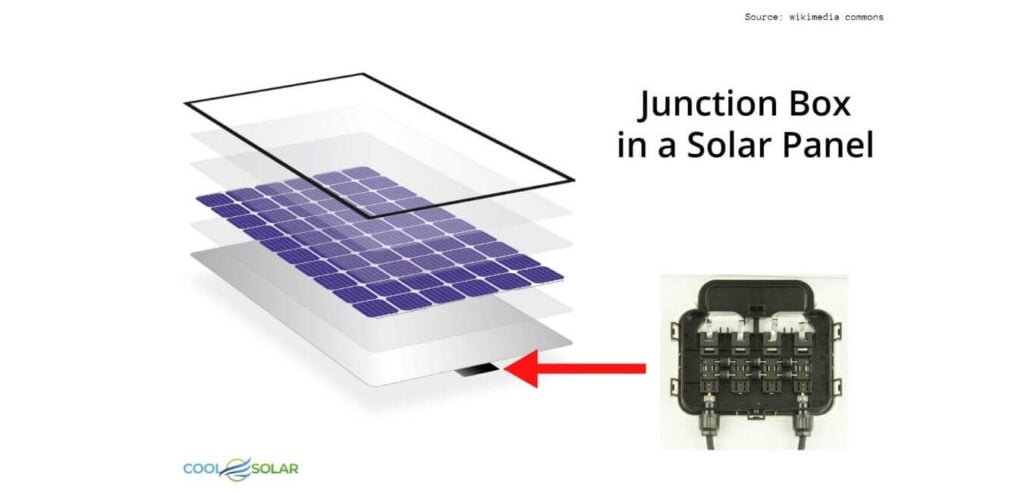

The junction box is a container mounted to the backside of the module and covers the connection of cell strings from the modules to the external terminals. It is also known as a junction box enclosure.

In most cases, the junction box comprises bypass diodes, which are used to safeguard the cells in a string in the event of a hot spot or shadowing.

This is one of the major problems with solar panels. Here are some causes of the junction box failures.

- The junction box is not properly attached to the back sheet.

- Junction boxes that have been opened or improperly closed as a result of a defective manufacturing procedure.

- Ingress of moisture, resulting in corrosion of the connectors and the string junction box interconnects

- Internal arcing in the junction box due to faulty wiring.

Potential Induced Degradation (PID) Effect

A well-known solar panel defect is potential-induced degradation (PID), which may cause photovoltaic (PV) panels to lose up to 80% of their power production. PID can be caused by a variety of factors, including temperature, humidity, and sunlight. Reduced power usage may occur gradually over time or may be seen immediately after installation.

Due to sodium ion migration from the glass plate to the cell via encapsulation and anti-reflective coating (ARC), the performance of the cell may decrease. And also an incorrect string earthing configuration results in a negative potential being generated across a semiconductor in the cell in relation to the cell’s encapsulation and support structure.

So it is essential to detect and address the PID issue as soon as possible in order to ensure that the performance of PV modules is maintained throughout the system’s lifetime.

Solar Panel Delamination

Delamination of solar panels may develop for a variety of causes. Here are some of them.

- Panel glass cover scratches.

- Internal rust. (corrosion)

Solar cells are very fragile in and of themselves. As a result of improper packing and handling, scratches on glass coverings may occur. The damage to the coating allows for the entry of air and dust, as well as water, which causes the rest of the coating to lift and ultimately delaminate.

When moisture seeps into the panel, interior corrosion begins to take place. Panels must be fully airtight and waterproof in order to function properly. This is accomplished by vacuum laminating the solar panel’s components together.

However, if the lamination process is not carried out correctly or is carried out for an insufficient amount of time, delamination may occur during the operation.

Back Sheet Degradation

To ensure the safety of the electric components from direct exposure to the environment, back sheets are used. The back sheet is located between the encapsulation and junction box of the solar panel.

Back sheets for photovoltaic (PV) modules offer important moisture, mechanical, and electrical insulation, but their continuous usefulness is dependent upon their ability to remain properly adherent during years of harsh environmental exposure.

Most cheap (low-cost) PV systems manufacturers are using low-quality materials to make these back sheets. So even after a few years or months, the adhesive part of the back sheet is dissolved. Resulting in delamination effects and serious safety issues.

Conductor Ribbon Defects

The front and rear contacts in solar cells have two essential components:

- Front contacts.

- Back contacts.

The current in the external circuit flows through these components. As current is transported via bus strips that are soldered to the front and back contacts, a short-circuit fault occurs when these strips get disconnected. The loss of output power is linked with a failure of the string ribbon. Thermal expansion and contraction or repetitive mechanical stress cause connections to fail.

Another contributing factor for conductor ribbon defects is thicker ribbon or kinks in ribbon, which cause connector breaks and open-circuited cells resulting in solar panel failures.

Hot Spots

As the word explains itself, hot spots in solar panels are the places that became excessively warm due to badly-soldered connections.

It is produced by poorly soldered connections in the cell, which causes a reduction in resistance in the part of the panel that receives the energy generated by the cell. This may result in a rise in voltage, which can cause the formation of a hotspot in the soldered regions.

An eventual short circuit and solar panel breakdown are possible outcomes of this occurrence, which may also result in decreased performance and lifespan of the photovoltaic panel.

It is possible to identify hot spots on your solar panels using thermo-vision evaluation, which makes use of thermography, which employs infrared video and still cameras to measure the surface temperature of the solar panels

Defective Bypass Diode

Parallel to the solar cells, bypass diodes are included inside the PV module. Partial shadowing of the PV module is reduced using these bypass diodes. So sometimes we experience that the solar panels are not working, or the performance decreases drastically.

Aside from power loss, the diode prevents the reverse biasing of single solar cells above the allowable reverse bias voltage. A cell reversed with a greater voltage than intended may develop hotspots that cause browning, burn marks, or even fire. Shock and mechanical stress can damage Schottky diodes. So human interaction without getting proper safety options must be avoided.

Snail Trail Contamination

B-grade solar cells are susceptible to damage from both the inside and the outside. A snail track is a grey or black discolouration of the silver paste used in the front metallised screen-printed solar cells which cause due to the use of a high concentration of silver in the paste. The result seems to be a snail trail on the front glass of the PV module

When the discolouration develops near the solar cell’s border, it is often associated with cracks in the solar cell that are not visible elsewhere. The development of the snail trails typically occurs 3 months to 1 year following the installation of the PV modules.

The initial rate of discolouration is influenced by the season as well as the surrounding environmental factors, such as sunlight exposure. As the summer progresses and as temperatures rise, it seems that snail tracks will become more common.

Micro Cracks

Microcracks are structural flaws in low-cost solar cells that are not visible to the naked eye, so these imperfections are referred to as microcracks.

Thermal cycles occur in the PV module as a result of the self-performance effect of the module, which occurs during transitions between day and night and between different seasons of the year. These defects have the potential to cause damage to the cell’s contact points, making it more difficult to evacuate the current.

In this circumstance, a solar cell may suffer significant degradation. Because PV modules contain serial connections within them, even if the cells are connected in a serial manner, the current of the entire panel will be limited, and the overall performance of the module will be reduced in proportion to the number of cracked cells.

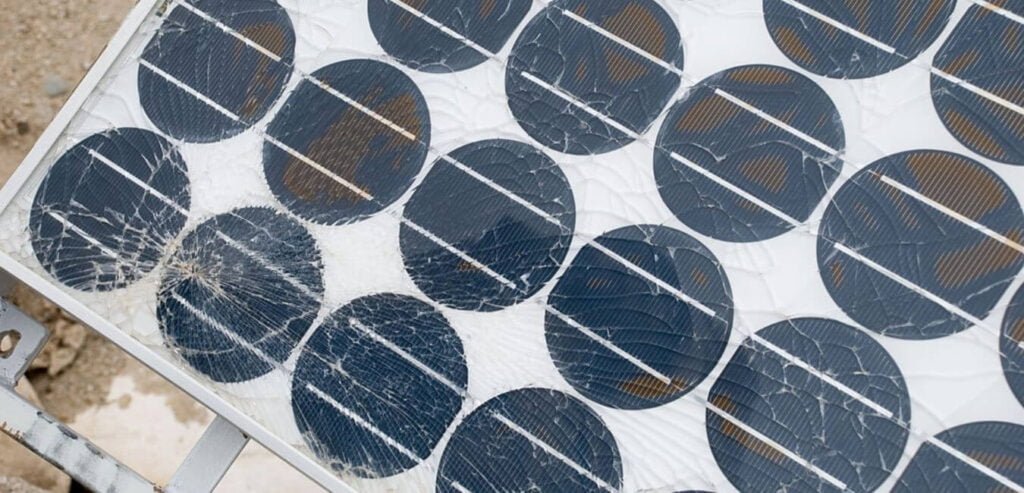

Broken Solar Cells

Some PV system manufacturers are utilizing low-quality solar panel cells (often referred to as B-grade solar cells) in their PV systems, which is a concern. These types of solar cells begin to fail over time as a result of the environment in which they are installed. Furthermore, solar cells are susceptible to breaking during hand soldering.

A thorough examination of your PV system can quickly reveal this problem.

Conclusion

In our in-depth research regarding the 9 most common solar panel defects, we discovered that the majority of the issues with solar panels are caused by the use of low-cost manufacturing materials by the manufacturers. A photovoltaic (PV) system is usually considered a long-term investment. Because of this, you must prioritize the dependability of your system over the total price. Environmental problems and faults with solar panels, such as those we discussed above, are very common. What you must do now is prepare yourself to examine and maintain your systems on a regular basis.

If your solar panels are not functioning properly or if you are experiencing solar panel issues, call Coolsolar Solutions, one of Australia’s top solar installers. We’ll provide you with the finest available solutions for any solar panel problems that you may be experiencing.